Pasture Management & Forage Improvement

The ultimate goal of pasture management is to efficiently convert forage into a saleable animal product. Using an appropriate grazing system can also reduce production costs and off-farm expenses while improving the health of the soil.

In order to achieve sustainable livestock production, producers must rely on growing forage as a primary feed source. Today’s producer needs to raise more on the acres they have – and good pasture management can help them do this.

Here you will find a collection of articles that offer helpful education information on how you can develop and maintain your pastures for maximum production and quality.

Rotational/Controlled/Managed Grazing

Gallagher advises this method as the best way to achieve optimum pasture yield as part of the milk/meat production process. This involves grazing paddocks in rotation using a combination of permanent and/or temporarily fenced grazing areas.

Key Benefits

- Effective – maximize results potential of feed and greatly improve the feed quality and yield

- Efficient – direct harvesting of grass or fodder crops by animal with the manure returned directly to the soil during the process.

- Flexible – use a combination of permanent & portable fencing to maximize grazing area control

Key Considerations

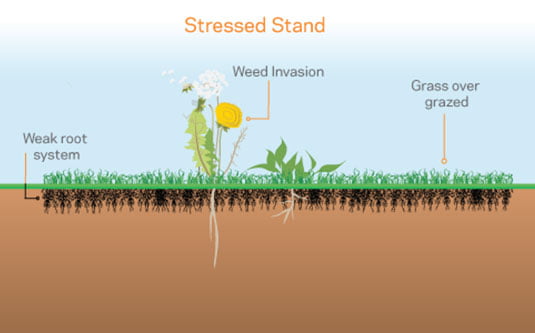

Achieving optimum pasture growth is a delicate balance. When considering how best to meter out the pasture feed available look at the following:

Number & size of grazing areas – grazing specific areas, while ensuring other pasture sections are able to rest and re-grow.

How many animals to put on that grazing area?

stocking density determines how efficiently the allocated area is grazed.

And for how long?

Graze to achieve the desired residual grass height (typically 3.5-4 cm) to maintain healthy forage, good root reserves and maximum growth between grazing. The more regular the shift (preferably daily or every few days) the more time the pasture spends growing rather than being grazed, leading to greater grass growth and stock carrying capacity.

The combination of these factors determines the rotation length (how many days before the first area in the rotation is grazed again). The optimum rotation length varies significantly depending on the geographical location and time of year.

Where a permanently fenced paddock is further subdivided using portable electric fences the stock are contained by both a front and a back fence. The back fence protects the recently-grazed area to allow it to recover so it can be grazed again earlier.

Subdivision with high stocking density ensures grass is harvested down evenly to the optimum residual length, and that over time manure is spread more evenly over the whole grazing area.

Why It Works:

Grass

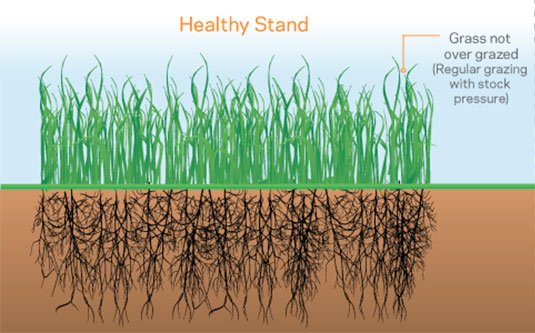

Using effective grazing methods maintains grass at the high growth stage. This is young, lush, green pasture with high protein and high energy levels. Grazed and rested for the right amount of time creates the optimum conditions for grass growth when the plants produce leafy shoots from the base.

To encourage these shoots to grow, regular but controlled grazing is required.

There are various grass varieties to suit different environments. Longer term options last 10 years or more and shorter term annuals can give extra yield over a shorter timeframe.

Forage crops (e.g.: turnips, kale, sourghum etc)

These are low cost to establish and can be used to fill feed deficits during cold and/or dry months where grass growth slows or stops altogether. Direct grazing of such crops using portable electric fencing eliminates harvesting and feeding out, with animal waste being returned directly to the land.

Systems Snapshot:

Permanent subdivision

Gallagher permanent electric fences provide secure containment or exclusion and are in most cases the least cost to own over the long term. Gallagher fence components typically carry a 10 year warranty and will last much longer than that in most situations.

Permanent Gallagher electric fences are:

- Low cost compared with conventional non-electric fences

- Fast to install

- Long life

- Better animal control

- Improved animal welfare outcomes (smooth wire = no hide damage like conventional barbed wire systems)

Gallagher produces systems for all animal types – cattle, sheep, goats, horses plus animal exclusion such as deer

Fencing layout should be designed to make stock movements easy, and to facilitate further subdivision using portable fencing. Wiring and power flow should be designed to make fence maintenance and fault finding a breeze. Laneways enable stock to be moved to yards easily for treatment etc. Gateways between paddocks make stock movements to the next grazing area straightforward.

Portable subdivision

Easy to transport, assemble and take down Gallagher portable fencing systems allow total flexibility for grazing area and time either within a permanent electric fence system, or within a traditional, non-electrified fence system using portable energizer power.

Read through the more specific types of electric fencing systems either as an overview or by animal or jump straight to our Getting Started section to see which product sets are best suited for your property and animal type.